Envetec Insight

Mechanical vs. Chemical Recycling:

Friends or Foes?

In the global effort to reduce waste and build a circular economy, recycling is at the forefront of sustainability strategies. Two primary methods of recycling – mechanical and chemical – have emerged as key players in this movement. But are they rivals competing for dominance, or can they function as complementary partners in the fight against waste through biohazard waste treatment?

Understanding Mechanical Recycling

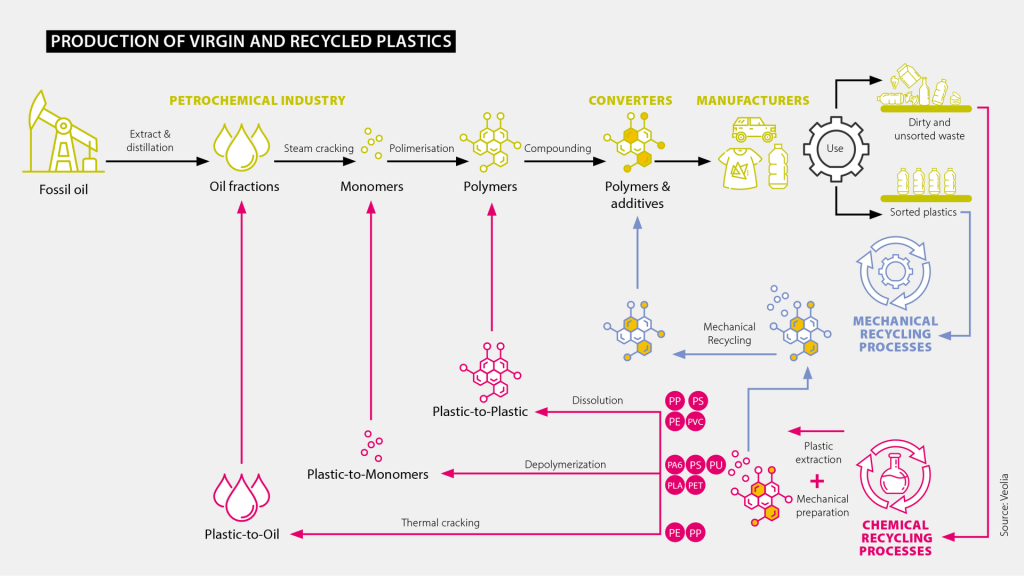

Mechanical recycling is the traditional method that involves physically processing waste materials, particularly plastics, into new products without altering their chemical structure. This process typically includes sorting, shredding, washing, and melting the plastics, which are then moulded into new products. One of the significant advantages of mechanical recycling is its relatively low cost and energy consumption. It is an established and well-understood process, making it a practical choice for recycling commonly used plastics like PET (polyethylene terephthalate) and HDPE (high-density polyethylene). Mechanical recycling accounts for the majority of plastic recycling worldwide, including efforts for clinical waste collection in regions like Ireland, the UK, and the US.

However, mechanical recycling has its limitations. The process is highly dependent on the quality and purity of the input materials. Contaminants, such as food residues or different types of plastics, can degrade the quality of the recycled material, limiting its applications. Additionally, each cycle of mechanical recycling tends to degrade the polymer’s properties, making the recycled material less suitable for high-quality applications over time.

The Rise of Chemical Recycling

Chemical recycling, also known as advanced recycling, is a novel process relative to mechanical recycling that breaks down plastics into their original chemical components. This method involves converting plastics into monomers or other valuable chemicals, which can then be used to create new plastics with properties identical to virgin materials.

One of the primary benefits of chemical recycling is its ability to handle a broader range of plastic types, including those that are difficult or impossible to recycle mechanically, such as mixed plastics or multilayered packaging. This makes it relevant for industries involved in biohazardous waste recycling and regulated medical waste treatment companies. Additionally, because chemical recycling processes the plastic at the molecular level, the resulting material can be of very high quality, suitable for applications that require high-performance plastics.

However, chemical recycling is currently more energy-intensive and costly compared to mechanical recycling. It also requires significant investment in infrastructure and technology, as the processes involved are more complex and less developed on a large scale. Despite these challenges, chemical recycling is rapidly gaining attention as a critical component of future sustainability strategies.

Complementary Roles in a Circular Economy

Rather than viewing mechanical and chemical recycling as rivals, it’s essential to recognize their potential as complementary technologies. Each method has unique strengths that can be leveraged to enhance overall recycling efficiency and effectiveness.

Mechanical recycling is well-suited for high-volume, relatively clean plastic waste streams, where it can provide a cost-effective and energy-efficient solution. On the other hand, chemical recycling can handle more complex and contaminated plastics, converting them into high-quality materials that can be reintroduced into the production cycle. This synergy is particularly useful in biohazard waste disposal, ensuring that more plastics and waste materials are kept out of landfills and incinerators.

The Future of Recycling: A Unified Approach

As the world continues to grapple with the challenges of plastic waste, a unified approach that integrates both mechanical and chemical recycling will likely be essential. By combining the strengths of both methods, we can create a more resilient and adaptable recycling infrastructure capable of handling the diverse and growing waste streams of the future, including sectors focused on biomedical disposal waste.

Investments in technology, infrastructure, and public policy will be key to realizing this vision. As chemical recycling continues to advance and mechanical recycling processes become more efficient, the potential for a circular economy where all plastics, including those from clinical waste collection and medical waste recycling, are reused and recycled will become increasingly attainable.

In conclusion, mechanical and chemical recycling are not rivals but potential partners in the global effort to reduce waste and promote sustainability. By embracing both methods and leveraging their unique strengths, we can take significant strides toward a more sustainable future.

Previous article

« Envetec Sustainable Technologies Completes Fundraise and Appoints New Chair

Next article