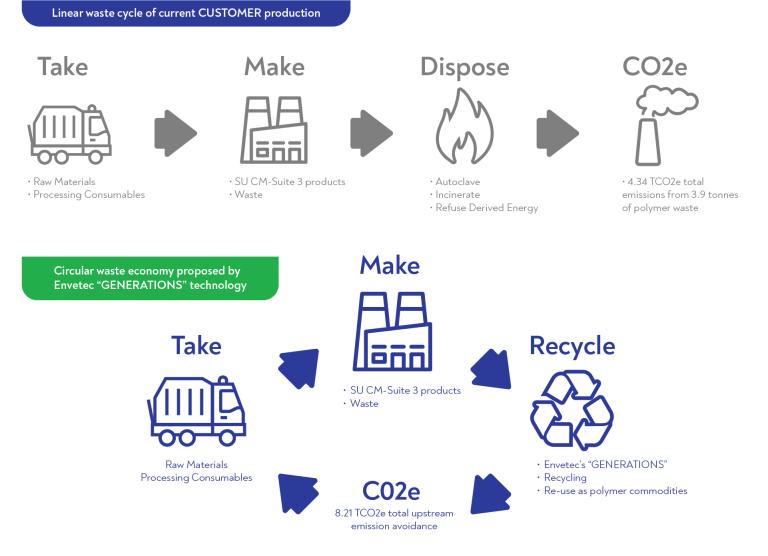

Biohazardous waste has long been managed through energy-intensive processes such as autoclaving, incineration, and landfill. While compliant, these methods are environmentally damaging, generating high greenhouse gas emissions, consuming millions of litres of water, and leaving little room for circularity. Determined to lead with innovation, one biopharma manufacturer sought a cleaner, safer, and more sustainable alternative; one that could align with ambitious emissions reduction targets and demonstrate environmental responsibility at scale.

From High Emissions to a Circular Future

This biomanufacturer faced multiple challenges:

- High emissions – traditional methods produced over 111 tonnes of CO₂e per 100 tonnes of waste.

- Excessive resource use – legacy systems consumed up to 1.17 million litres of water for every 100 tonnes processed.

- No recycling potential – incineration and landfill eliminated any chance of circularity.

Envetec’s GENERATIONS technology offered a breakthrough solution. By shredding and disinfecting waste directly on-site at ambient temperatures, it eliminates transport miles, reduces reliance on fossil fuels, and transforms biohazardous plastics into a clean, flake-like material ready for recycling. This forward-thinking approach not only simplifies compliance but also unlocks real opportunities for circularity.